VEB Robotron Elektronik Dresden, 1974 | Bundesarchiv | CC-BY-SA-3.0

The concept of “Industry 4.0”, also known as the Industrial Revolution 4.0, smart industry or cyberindustry of the future, refers to a new way of organising production media characterised by a fusion of technologies that is blurring the lines between the physical, digital and biological spheres. It represents the start-up of a large number of smart factories, opening up the way to a new industrial revolution. And as in the previous industrial revolutions, two discourses coexist: one based around economic growth and the other around the promise of a better world that puts the community at the centre.

In the territory of the mythical /quasi-fake/fake there is a version doing the rounds about how the “4.0” was conceived. Let’s go back to 2011. A committee from the German Forschungsunion Wirtschaft-Wissenschaft presented a research and innovation programme to Chancellor Merkel under the title “Industrial Revolution 4.0“. It was a clever action plan. It was postulated as the response to the evident domination of the new flows of innovation, creativity and production by actors that were not precisely the heavyweights of German industry but the new digital giants, mainly American. The plan was a defence of physical production, the production of things, a field in which Germany was strong. From that strength it was necessary to take advantage of the digital in order to position itself with an advantage in the battlefield that those with a “start-upist” vision, Silicon Valley, had started to play. And to dominate.

What was new in all this?

The relationship between information, communication and production is an old one. Logistics, for example, is very critically dependent on having timely and veracious information on supply needs and production capacities and on their synchronisation. Manufacturing, strictly speaking – since Tayler – requires a great deal of information. From initial designs to plans, to the status of material in warehouses, to the pace of production of an assembly line to the individual performance of those who form part of that line, it is all information. Robots, that materialisation of information to act with a certain intelligence, had already been in plants for dozens of years. The Internet connected them with databases, warehouses, part designs and people to accelerate all the production, supply and distribution up to speeds that we find normal, at the cost of a technical and computational complexity that was unsuspected until recently. A package from Amazon Prime reaching our home in less than an hour seems natural to us now, but was not at all normal until very recently.

So, what is new about 4.0? Here we welcome Klaus Schwab. Schwab is as German as Merkel but he is also the deviser, organiser and promotor of a well-known club of friends: the World Economic Forum, otherwise known as the Davos Forum. And he floated the idea of the Revolution 4.0 among them. In his own words:

We stand on the brink of a technological revolution that will fundamentally alter the way we live, work, and relate to one another. In its scale, scope, and complexity, the transformation will be unlike anything humankind has experienced before. We do not yet know just how it will unfold, but one thing is clear: the response to it must be integrated and comprehensive, involving all stakeholders of the global polity, from the public and private sectors to academia and civil society.

The First Industrial Revolution used water and steam power to mechanize production. The Second used electric power to create mass production. The Third used electronics and information technology to automate production. Now a Fourth Industrial Revolution is building on the Third, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

It is an argument, a style and a rhetoric that we already know from other “pointzeros”. We can trace its air of a family, for example, in the announcements of the opening up of the Internet to commercial use, and subsequently, with the arrival of 2.0. For example, in times of Tim O’Reilly, the following was said about “2.0”:

The Web 2.0 refers to World Wide Web sites that emphasise user-generated content, usability (ease of use, even by non-experts) and interoperability (this means that a website can function well with other products, systems and devices) for end users…

Technically, the closest part to “4.0” in the case of 2.0 is interoperability. A system that has been designed taking a second or third system into account – located in any other part of the world – can act or interact with them, interoperate. This recalls the connection of very diverse 4.0 systems: logistics chains, transport systems, decision-making systems, etc.

What is rather different about 4.0 is what Schwab takes to its logical conclusion: the identification of information with its bio and material correlate. If you have a plan in Barcelona, someone can download and manufacture it in China. Now it is rather more than common. If, previously, within this complexity we placed people to pilot these processes, now Schwab and Friends suppose that there will be artificial intelligence in their place. In other words, with 4.0 what is connected is no longer materials and repositories of content and information controlled by programmed and repetitive processes, but also certain types of smart agents that can make decisions inserted at a determined point of the logistics, production and distribution chain. With one more turn of the screw and by connecting and stretching considerably what is producible with the biological “Fourpointzero” Schwab is saying that if you have the description of their DNA, you have the programme to “manufacture” living beings and insert them into this universe of smart agents 4.0.

What resonates in all of these statements is the tune of efficiency and economic growth:

In the future, technological innovation will also lead to a supply-side miracle, with long-term gains in efficiency and productivity. Transportation and communication costs will drop, logistics and global supply chains will become more effective, and the cost of trade will diminish, all of which will open new markets and drive economic growth.

Schwab dixit. We are already familiar with this tune. From time to time it is seasoned with a reference to the exponential growth of capacities and results.

Thus, then, the horizon drawn by 4.0 is homogeneous and continuous with the other pointzeros: to a policy of economic dominance based on the exceptional use of another technology and its combinations with others that already exist, all based on information.

The 2.0 seduced us with promises of collaboration, of contribution to the conversation, to community-building. However, it has also led us to the current realities of extractive data capitalism. With regard to 4.0, it may be a necessary and urgent exercise to speculate on its future directions. This complex interconnection of the physical and the material, the digital and the living, the repetitive and the intelligent, is animated by the same values and the same logic that has piloted the previous pointzeros. Even Schwab himself alerts to the “disruptive” (an adjective that cannot be lacking in any pro-technological narrative) changes in numerous spheres of life: environment, everyday life, forms of work (or its disappearance), etc.

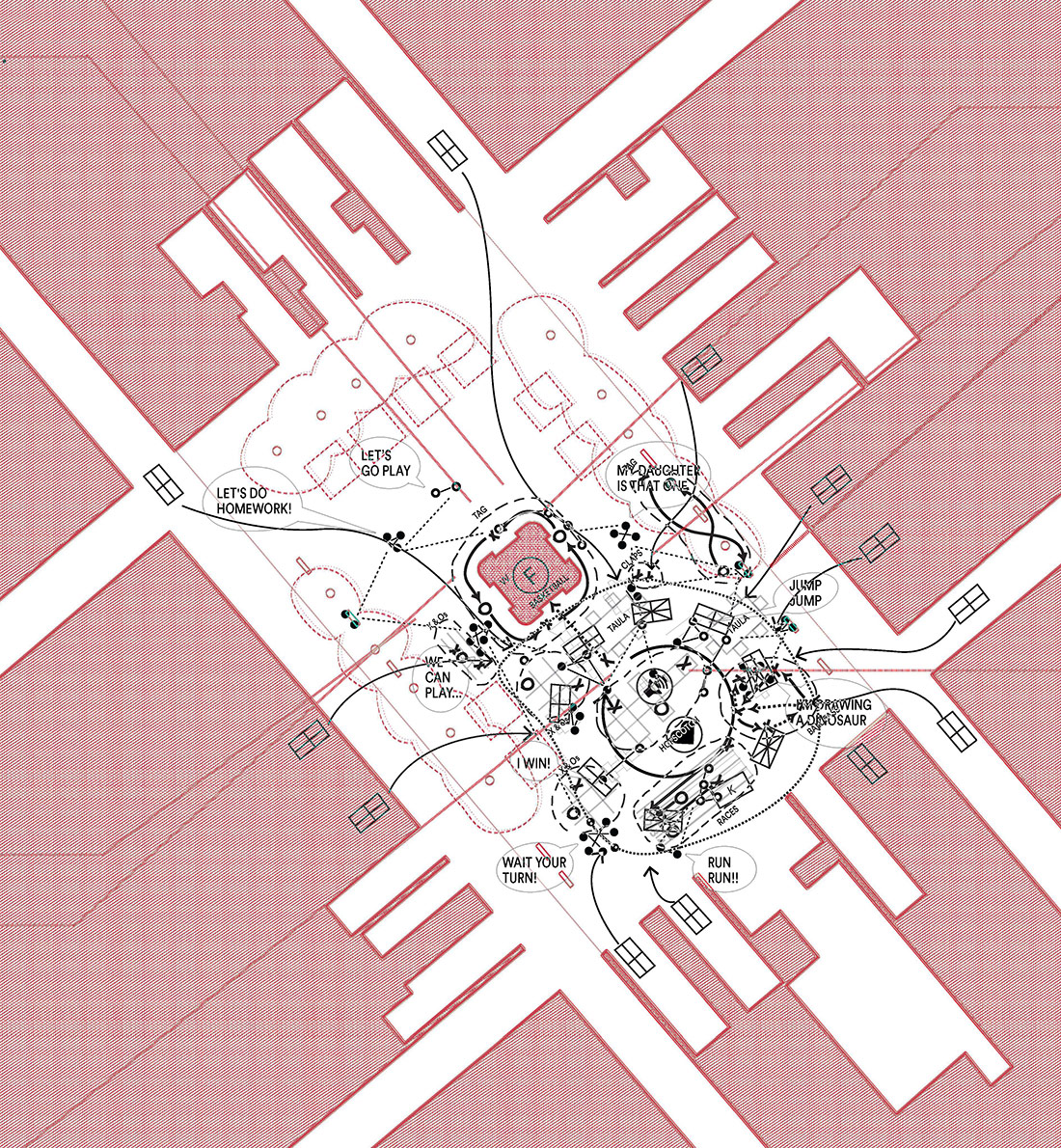

Design For City Making | Elisava | Unknown rights

In the face of the hegemonic fourpointzero, an alternative policy and discourse appear that also resort to manufacturing. They argue that if we can distribute manufacturing capacity in small facilities that are close either to consumers or to producers or to both, perhaps we can create other alternative economic models. Or seek new sustainabilities from manufacturing. Or alternatively organise cities differently, third parties point out.

Certainly, if in the city we distribute these resources in an way accessible to the population it would be possible, in theory, to create new urban production and logistics chains where users are also producers (here the “prosumers” of the old 2.0 days strike again). They could manufacture their own products whether organic or made of other materials, food or clothing. Here there is a mix that we already know: trust in a new technology viewed from the angle of a new communitarianism structured once more around the same production technologies that have been created and used by the economic giants. In other words, there are proposals to use under another concept of benefit different to that of the capitalist one those fourpointzero technologies dominated by the major actors in the digital sphere. These include everything from fablabs to other manufacturing spaces.

Perhaps it should be necessary to investigate how to again avoid the consequences that we already know from our experience with the previous pointzeros. In the project “Design for City Making”, for example, we are exploring how to create a production and distribution commons based on digital manufacturing technology resources. The intersection between artisans, digital artisans, the usual “makers”, “bricoleurs”, “handymen” and an open and small-scale but highly replicable version of digital production technologies, encourages a community-based view with values different to those of the 4.0 of the Schwab version. It is an ambiguous territory where we can anticipate the difficulties of constructing the digital-common that we already experienced in the times of 2.0, when we were all going to build a commons of contents and knowledge, and ended up rather as non-remunerated producers for third parties. Piloting all of this is not at all easy. Can we avoid another new innocence?

Merkel very much liked the action plan presented to her by the Forschungsunion Wirtschaft-Wissenschaft but she suggested a change, just a minor one: instead of being called “Industrial Revolution 4.0″, the plan of the Forschungsunion Wirtschaft-Wissenschaft should be called pure and simply “Industry 4.0”. A change without importance, a little whim of power, virtually nothing at all.

Brynjolfsson and A. McAfee (2014). The Second Machine Age: Work, Progress, and Prosperity in a Time of Brilliant Technologies. New York: W. W. Norton & Company

Martínez, A. Mestres and M. Hinojos (eds.) (2017). Deconstruyendo el Manifiesto Maker. Barcelona: Trànsit Projectes–MakerConvent, pp. 18-33.

Schwab (2017). The Fourth Industrial Revolution. New York: Crown Publishing Group.

Schwab (2016). The Fourth Industrial Revolution What it Means and How to Respond. Accessed on 25 May 2018.

Tiqqun. La hipótesis cibernética. Accessed on 22 March 2018.

Celia | 17 July 2018

Creo que el hecho de que Merkel prefiriese que desapareciese el término “Revolución” del título es más que sugerente. Me recuerda a las palabras de Le Corbusier en “Hacia una Arquitectura”, el último capítulo “Arquitectura o Revolución”, acaba con una especie de aforismo que dice mucho del arquitecto y de la arquitectura moderna: “Arquitectura o Revolución. La Revolución se puede evitar”.

Es lo mismo.

Para las élites, la revolución siempre se puede evitar, y quedarse simplemente con una técnica (4.0) envuelta de un halo falsamente neutral y benéfico.

Leave a comment